Product List

Servers

Welcome to TONGLI Machinery

Tongli Charcoal Making Machine

Introduction to Charcoal Making Machine:

Charcoal plays an important role in many countries and charcoal making machine is becoming important and necessary for fast or large amount charcoal production. Modern methods for charcoal production is using a sealed metal container called charcoal making machine.

The charcoal produced by charcoal making machine is call extruded charcoal which is made by extruding either raw ground wood or carbonized wood into logs without the use of a binder. The heat and pressure of the extruding process hold the charcoal together.

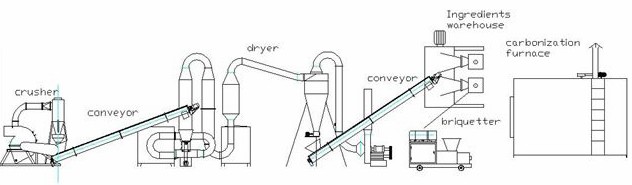

The general charcoal production flow can be Raw Material Crushing--Drying--Shape Forming--Carbonization--Final products. So the charcoal making equipment shall be Crusher--Dryer--Charcoal Making Machine(shapes:logs, rods, briquets, etc.)--Carbonization Furnace and other auxiliary equipments.

Advantages of Machine-Made Charcoal:

- Higher charcoal yield.

- Rapid carbonisation.

- Charcoal can be made from raw materials that cannot be processed by traditional methods.

- Industrial chemicals and heat energy can be recovered from the smoke given off during carbonisation.

- Recovering from the smoke, so there is less pollution to the environment.

The carbonization of wood is brought about by heating it to temperatures high enough for it to undergo substantial thermal decomposition. Temperatures reached in the process are usually in the range 400-500℃ and a mixture of gases, vapors and a solid residue (charcoal) results. The temperature reached in the production process has a marked influence on the composition and yield of the charcoal produced.

Email:

Email: