Product List

Servers

Welcome to TONGLI Machinery

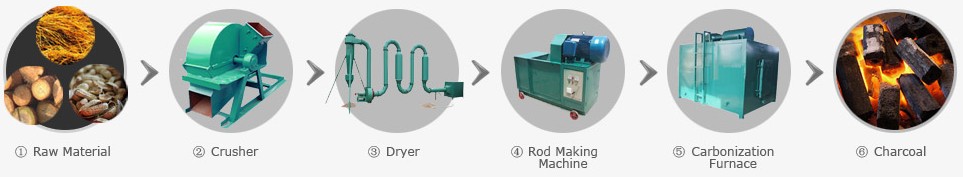

Workflow of Charcoal Production Line

By charcoal making machine, wastes like wood waste, forest waste, coconut shells, rice hulls and olive scum that can be recycled by grinding, drying and formed into rod material, then users can get charcoal sticks by carbonization in carbonization furnace.

Below is the workflow of charcoal production line:

First step(Crushing): crush the raw materials into small pieces (3-5mm) by wood crusher/Hammer Mill;

Second step (drying): dry the crushed materials by sawdust dryer to reduce the crushed material's moisture content below 8-12%

Third step(briquetting): Put the dried materials into the rod making machine to make sawdust briquettes. This stick is 45-80mm in diameter, occurs in the hollow quadrangular or hexagonal cylinder or hollow hexagonal with a 15-20mm hole through the body.

Last step(carbonizing): Carbonization furnace for biomass charcoal can greatly increased carbonizing ratio (increased from about 88% to 99%) and shortened the carbonizing time (from 24 hours to 8 hours), and shows the features of easy operation, higher safety, high efficiency, and energy saving. This furnace is ideal equipment for wood briquettes to have anoxic distillation carbonization.

Gongyi Tongli Machinery Factory is specialized in manufacturing charcoal equipments including crushers, screens, dryers, conveyors, charcoal making machine, charcoal powder moulding machine, carbonization furnaces and purifiers.

Tongli charcoal briquette machine and charcoal production equipments have been exported to Russia, Uzbekistan, Myanmar, Vietnam, Laos, Kazakhstan and many African countries. For more information, please view our website or contact us via the following Email.

Homepage/ http://www.cncharcoalmachine.com

E-mail/ evelyn@cncharcoalmachine.com

Email:

Email: