Product List

Servers

Welcome to TONGLI Machinery

Desulphurization gypsum ball press

Brief Introduction of Desulfurization Gypsum Ball Press Machine:

Ball press is generally roll-to-roll ball press, which can be divided into desulfurization gypsum ball press (also known as gypsum powder ball press), briquette ball press, pulverized coal ball press, etc. according to its use, but the structure of the ball press is basically the same. The main working parts are two rollers.

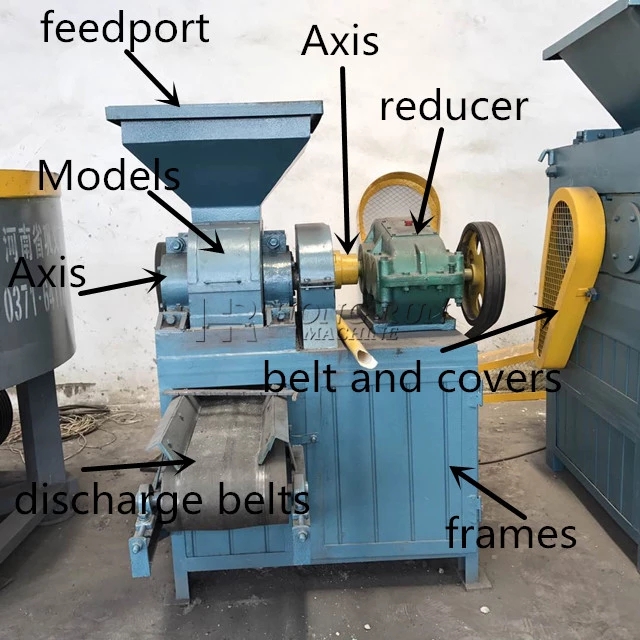

Composition of Desulfurization Gypsum Ball Pressing Machine

The structure of desulphurization gypsum ball press consists of two parts: one is the feeding part, the other is the transmission part.

The feeding part mainly realizes the quantitative feeding to ensure that the material evenly enters the counter-roll room. The screw feeding device is driven by an electromagnetic speed regulating motor and rotates through the belt pulley and worm reducer, forcing the pressed material into the main inlet and outlet. Because of the constant moment characteristic of the electromagnetic speed regulating motor, when the pressure of the screw feeder is equal to that of the main machine, the constant pressure of the feed can be maintained to stabilize the quality of the pellets. If the feeding quantity is too large, the electric overload of the feeding device will occur; if the feeding quantity is too small, the ball will not be formed. Therefore, skilled operation is an important condition to ensure the normal operation of pressure ball.

In the transmission part, the main transmission system is: motor - triangle belt - reducer - Open Gear - roll. The main engine is powered by an electromagnetic speed regulating motor, which is transmitted to the driving shaft by a bar-pin coupling through a transdermal belt pulley and a cylindrical gear reducer. The driving shaft and the passive shaft run synchronously through the open gear. The rear of the passive bearing seat is equipped with a hydraulic device. Hydraulic protection device is a hydraulic pump which injects high-pressure oil into the hydraulic cylinder to produce axial displacement of the piston. The front joint top of the piston rod is on the bearing seat to meet the production pressure requirement.

Next: Iron powder ball press Previous: Counter-Roller Press Ball Machine

Email:

Email: